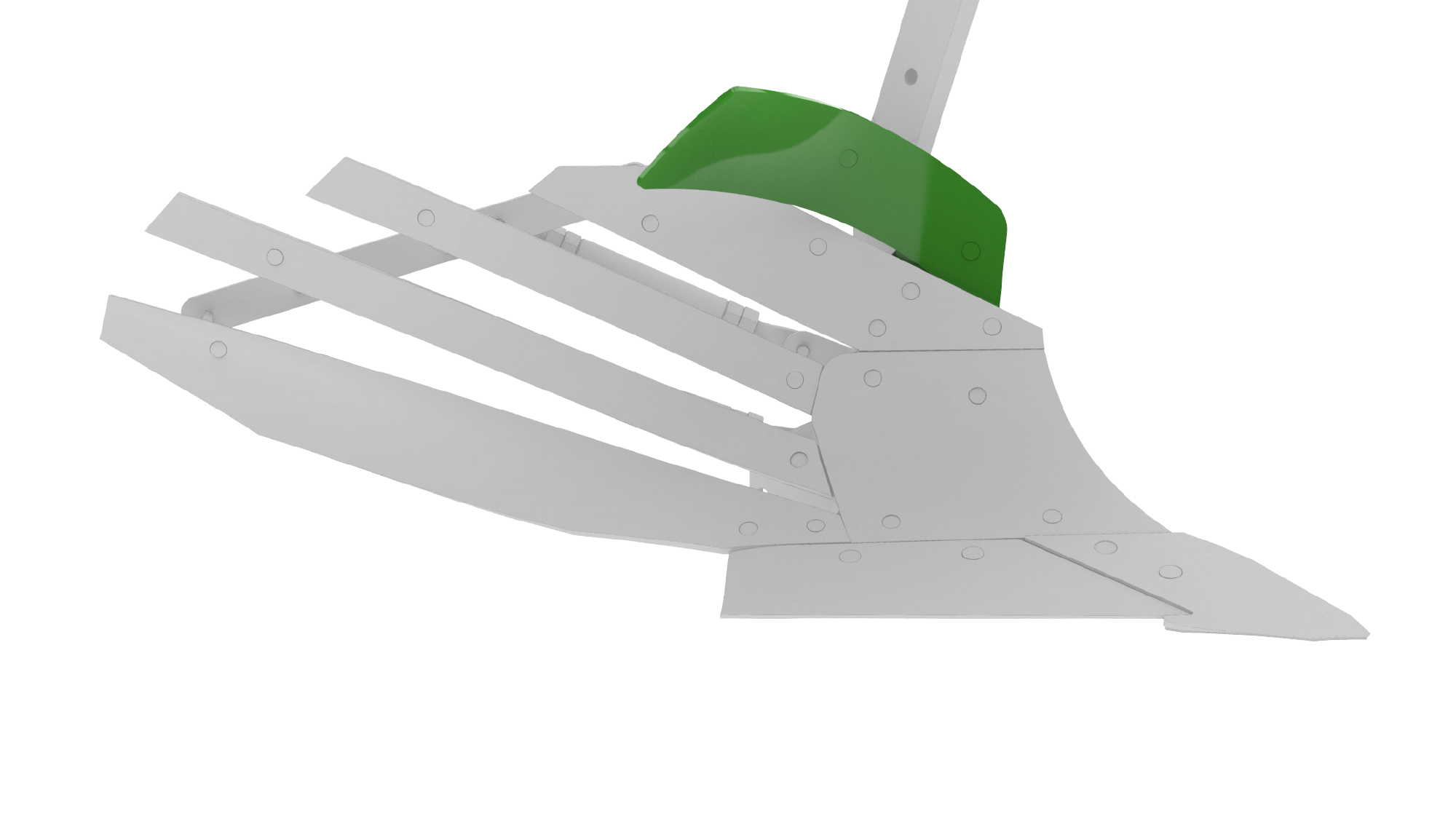

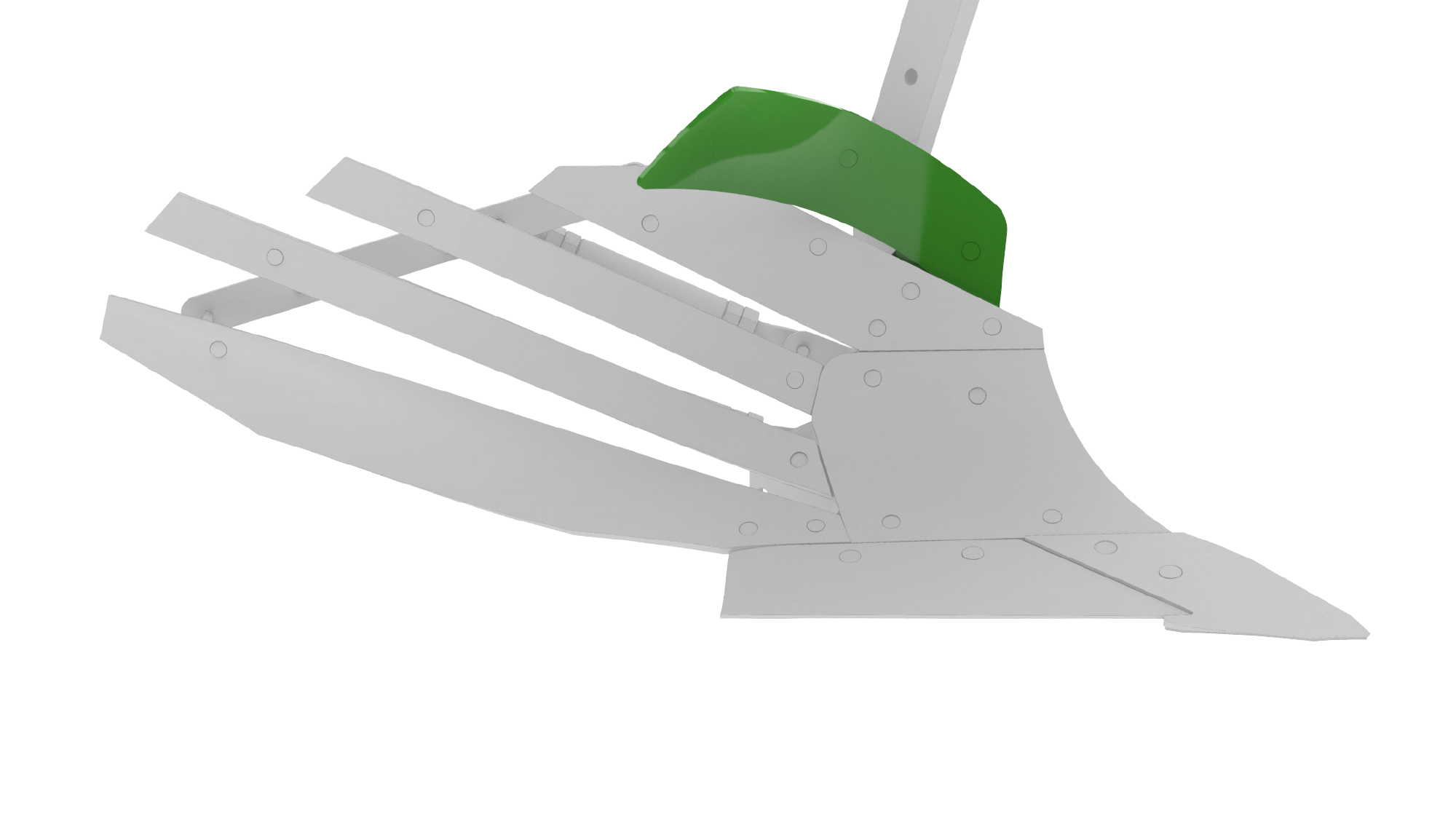

Trash boards:

a cost-effective alternative to skimmers when incorporating surface crop residues. With additional support on the leg as standard.

Sword landsides:

The sword landside is an alternative to the disc coulter, which, especially on heavy, stony ground ensures a clean furrow wall and also reduces the wear and tear on the plough body.

Landside protection:

The landside protection increases the area for support of the plough on the furrow wall. This improves plough guidance significantly, especially on slopes. In order to enable the use of wider tyres in the furrow, a furrow-widening plate can be installed as an option on the last plough body.